F serial fixed flange’s protective tube is setting outside the temperature measurement component when thermal couple and resistor is working, and it has the anti-corrosion effect and defends against agent’s pressure, which makes the output of measurement component precisely reflect the temperature. It has the following characteristics:

1. According to IEC international standard design

2. High concentricity and deep hole processing. Anti-high pressure, temperature and liquid speed.

3. Can be manufactured and installed with the equipment at the same time;

4. Different pressure demands to meet different environments and industries.

5. According to customers’ need, we can provide extra long protective tube more than 1.5 meter long.

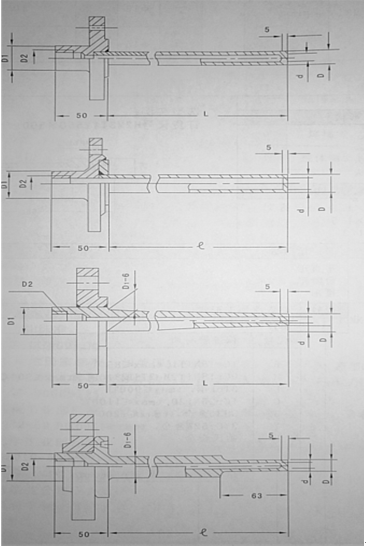

1)Combining form

Flange | Drawing | Measuring-end | ||

Code No. | Type | Code No. | Type | |

F1 | Single Side Welding Fixation Flange |

| P | Flat Straight Pipe |

F2 | Sealing surface Embedding welding Fixation Flange | |||

F3 | Double Side Welding Fixation Flange | Z | Taper Pipe | |

F4 | Loose Cover Flange | T | Step Pipe | |

2) dimension parameter

Connection End Diameter D1/mm | Inner Thread D2/mm | Protecting Tube Shape | Measurement End Form | Nominal Pressure MPa | Related Dimension | Planting Depth mm | ||||

Code | Dimension | Code | Dimension | Specification | Code | Manufacture Method | D | d | ||

1 | φ28 | M1

M2

M3 | M16×1.5

M20×1.5

NPT1/2 | Flat Straight Pipe | 0 | Welding | 6.4 | φ16 | φ12 | 1、 For Pipe Of Whole Body Drilling: 100、150 200、250 300、350 400、450 500、550 600、650 700、750 800、900 1100、1150 2、 For Flat Straight Pipe: 1250、1500、2000

|

1 | Whole Body Drilling | 10 | φ22 | φ7 | ||||||

Taper Pipe | 1 | φ15 | ||||||||

Step Pipe | 0 | Welding | 6.4 | φ12 | ||||||

1 | Whole Body Drilling | 10 | φ13 | |||||||

2 | φ34 | Flat Straight Pipe | 0 | Welding | 6.4 | φ28 | φ16 | |||

1 | Whole Body Drilling | 30 | φ7 | |||||||

Taper Pipe | 1 | φ15 | ||||||||

Step Pipe | 0 | Welding | 6.4 | φ16 | ||||||

1 | Whole Body Drilling | 30 | ||||||||

1.When the sealing surface of the selected flange is concave and convex, the tongue and groove surface, the instrument provides the form of convex flange 3. When one side welding connecting the fixed flange with the protection tube requiring high strength and reliability, can provide thread fixed after add ring welding structure. | ||||||||||

3) protective tube materials and the use of temperature

Code No. | Material of Protective Tube | Long-term Temp. ℃ | Max Temp. ℃ |

B | 06Cr18Ni11Ti | 800~950 | 1050 |

M | Cr18Ni12Mo2Ti or 316 | 800~950 | 1050 |

L | 316L | 800~950 | 1150 |

C | 1Cr25Ni20 | 800~1000 | 1150 |

G | GH30 Alloy | 800~1050 | 1200 |

Y | 3YC-52 Alloy | 800~1200 | 1300 |

H | Hastelloy | 800~1200 | 1300 |

Note: The Long Term Working Temperature And Max Temperature May Differ Depending On The Atmosphere. | |||

所属分类:

所属分类: 打印当前页

打印当前页