We produce armored thermocouple cable made of excellent class I thermal couple. It adopts excellent stainless steel and high purity magnesium oxide with advanced manufacturing technique, certified by GB/T 1840 standard, with fine performance. Its surface is brightened.

We can produce precious or base metal armored cable with various graduations and specifications, which are indispensable in the production of armored thermal couples. Base metal armored cable is available all the time while precise metal cable must be ordered in advance.

Graduation: N, K, E, J, T, S, R, B

1) model and tolerance

Type | Model | Thermocouple | Ⅰ | Ⅱ | Ⅲ | |||

Range ℃ | Tolerance ℃(±) | Range ℃ | Tolerance ℃(±) | Range ℃ | Tolerance ℃(±) | |||

Ni Cr-Ni Si | KK | K | -40~1100 | 1.5 or 0.4%t | -40~1200 | ±2.5 or 0.75%t | -200~40 | ±2.5or 1.5%t |

NiCrSi-NiSiMg | KN | N | ||||||

NiCr-CuNi | KE | E | -40~800 | -40~900 | ||||

Fe-CuNi | KJ | J | -40~750 | -40~750 | —— | |||

Cu-CuNi | KT | T | -40~350 | 0.5 or 0.4%t | -40~350 | 1.0 or 0.75%t | -200~40 | 1.0or1.5%t |

PtRh10-Pt | KS | S | 0~1600 | 1or [1+0.003(t-1100)] | 0~1600 | 1.5 or 0.25%t | —— | |

PtRh13-Pt | KR | R | ||||||

PtRh30-PtRh6 | KB | B | —— | 600~1700 | 0.25%t | 600~1700 | 4or0.5%t | |

2) cable size

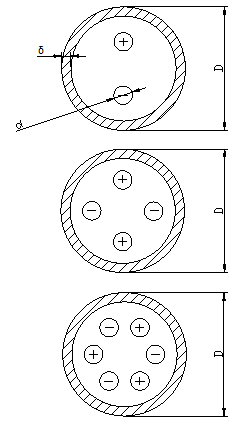

Nominal Valve of OD±Tolerance Value D/mm | Cores | Distribution of Negative and Positive | Length | Casing Wall Thicknessδmm | Diameter d/mm | |

Standard m | Max m | |||||

0.5±0.025 | 2 |

| ≥15 | 150 | ≥0.1D | ≥0.15D |

1.0±0.025 | 250 | |||||

1.5±0.025 | 150 | |||||

2.0±0.025 | 100 | |||||

3.0±0.030 | 2

4 | 95 | ||||

4.0±0.040 | ≥10 | 70 | ||||

4.5±0.045 | 55 | |||||

5.0±0.050 | 45 | |||||

6.0±0.060 | ≥5 | 30 | ||||

8.0±0.080 | 20 | |||||

0.5±0.025 | 6 | —— | ||||

0.5±0.025 | ||||||

0.5±0.025 | ||||||

Note: 1. when D=0.5, no S, R, B thermocouple is provided. | ||||||

3) insulation performance

Model | Test Conditions | Mini-insultation Resistance MΩ·m | ||||

Temp. | Test Temp. ℃ | Diameter of Sample D/mm | Length of Sample L/m | Test Voltage V·DC | ||

KK、KN、KE、KJ、KT、 KS、KR、KB | Room Temp. | 20±15 | ≤φ1.5

>φ1.5 |

1

|

75±25

500±50

| 1000 |

KK、KN、KE、KJ、KT | High | 500±15 | 0.5 | 5 | ||

KT | 300±15 | 500 | ||||

Note: When the length is below 1m, it's roughly considered as 1m. When it's above 1m, inlsulation resistance is calculated as R≥1000/L | ||||||

4) the maximum working temperature and test temperature

Model | Thermocouple | Material of Sheath | Outer Diameter mm | Max Working Temp. ℃ | Test Temp. ℃ | |

KN KK | N K | GH3030 | 0.5、1.0 | 500 | 300(250)、400、500 | |

1.5、2.0 | 800 | 400、600、800 | ||||

3.0、4.0、4.5、5.0 | 900 | 500、700、900 | ||||

6.0、8.0 | 1100 | 500、800、1100 | ||||

1Cr18Ni9Ti 316L | 0.5、1.0 | 400 | 200、300(250)、400 | |||

1.5、2.0 | 600 | 400、500、600 | ||||

3.0、4.0、4.5、 5.0、6.0、8.0 | 800 | 400、600、800 | ||||

KE | E | 0.5、1.0 | 400 | 200、300(250)、400 | ||

1.5、2.0 | 500 | 300(250)、400、500 | ||||

3.0、4.0、4.5、5.0 | 600 | 400、500、600 | ||||

6.0、8.0 | 800 | 400、600、800 | ||||

KJ | J | 0.5、1.0 | 300 | 100、200、300(250) | ||

1.5、2.0 | 400 | 200、300(250)、400 | ||||

3.0、4.0、4.5、5.0 | 500 | 300(250)、400、500 | ||||

6.0、8.0 | 750 | 400、600、750 | ||||

KT | T | 0.5、1.0 | 200 | 100、200 | ||

1.5、2.0 3.0、4.0、4.5、5.0 | 300 | 100、200、300(250) | ||||

6.0、8.0 | 400 | 200、300(250)、400 | ||||

KS KR | S R | GH3030 | 1.0、1.5 | 800 | 400、600、800 | |

2.0、3.0 | 900 | 400、600、900 | ||||

4.0、4.5 | 1000 | 600、800、1000 | ||||

5.0、6.0、8.0 | 1100 | 419.527、660.323、1084.62 | ||||

Note: For φ0.5、φ1.0、φ1.5 cable with N, K, E, T thermocouples, with 1Cr18Ni9Ti as outer pipe sleeve, , if requried, the testing temperature in sub-temperature area is -79℃ and -196℃. | ||||||

所属分类:

所属分类: 打印当前页

打印当前页