In the production of oil, gas, chemical and other industries, inflammable, explosive, corrosive chemical gas, steam and liquid is very common. In order to achieve industrial production automation, workers need a temperature sensor to automatically measure and control the process, while the use of aluminum alloy explosion-proof junction box can no longer meet the safety requirements for flame-proof .

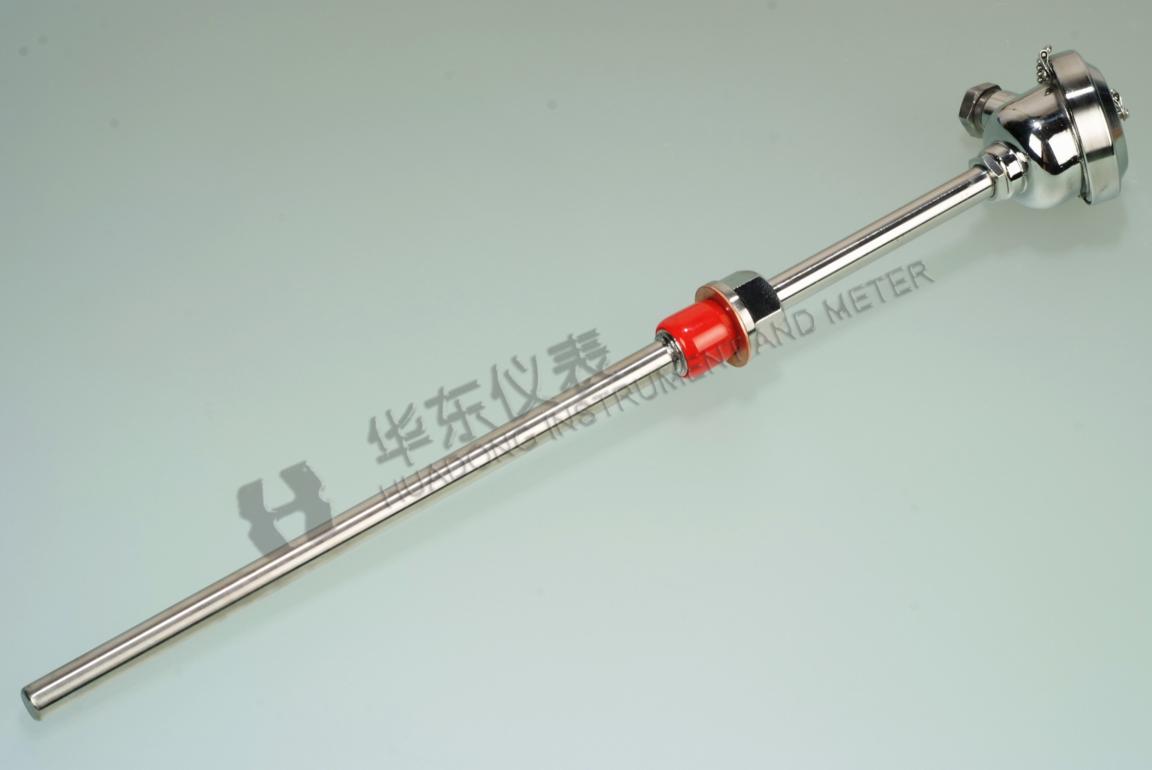

Flameproof thermocouple, thermal resistance, explosion-proof by the National Safety Supervision and Inspection Station test qualified and issued an explosion-proof series of product certification. It uses all stainless steel junction box and could be applied in ExdⅡBT4~5, ExdⅡCT1~6 which demands the highest level of protection---IP65, where corrosion and explosive atmosphere is around.

1) temperature and tolerance

Type | Graduation | Tolerance level | |||

levelⅠ | level Ⅱ | ||||

Temperature range | Tolerance | Temperature range | Tolerance | ||

Nicrsi-Nisimg | N | 0~1000℃ | ±1.5℃ or ±0.4%∣t∣ | 0~1200℃ | ±2.5℃ or ±0.75%∣t∣ |

Ni-Cr – Ni-Si | K | ||||

Ni-Cr – Cu-Ni | E | 0~800℃ | ±1.5℃ or ±0.4%∣t∣ | 0~900℃ | ±2.5℃ or ±0.75%∣t∣ |

Type | Graduation | Temperature range | Tolerance level | ||

Pt Resistor | Pt100 | -200~500℃ | level A:±(0.15+0.002∣t∣)℃ | ||

level B:±(0.30+0.005∣t∣)℃ | |||||

Cu Resistor | Cu50 | -50~100℃ | ±(0.30+0.006∣t∣)℃ | ||

Cu100 | |||||

2) models and specifications

Type | Graduation | Temperature range/℃ | Thermal response time/s | Long-term use of temperature and material | specification Total length × insertion depth | Note |

WRNK-240-dcP2 | N | 0~1200 | τ0.5≤90 | 0~1200 K1230、GH1230 | 300×150 350×200 450×300 500×350 550×400 600×450 750×600 900×750 1150×1000 1250×1100 1400×1250 1500×1350 1650×1500 1750×1600 2000×1850 2150×2000

| 1, junction box: small stainless steel junction box (P2); 2, protection tube: thermocouple type 0,1 corresponding to φ16, φ20, thermal resistance model 0,1 corresponding to φ16, φ12; 3, the process connection: fixed thread connection, commonly used M27 × 2, optional M33 × 2, NPT1 / 2 ", NPT3 / 4", NPT1 " 4, temperature measurement components: single, double armored components φ3, φ4, φ5, φ6, φ8 or assembly components. |

WRNK2-240-dcP2 | ||||||

WRNK-241-dcP2 | 0~1100 GH30 | |||||

WRNK2-241-dcP2 | ||||||

WRKK-240-dcP2 | K | 0~1000(φ8) 1Cr25Ni20、Cr25Ti | ||||

WRKK2-240-dcP2 | ||||||

WRKK-241-dcP2 | 0~800 06Cr18Ni11Ti

| |||||

WRKK2-241-dcP2 | ||||||

WREK-240-dcP2 | E | 0~800 | 0~800 06Cr18Ni11Ti | |||

WREK2-240-dcP2 | ||||||

WREK-241-dcP2 | ||||||

WREK2-241-dcP2 | ||||||

WZPK-240-dcP2 | Pt100 | -200~500 | -200~500 06Cr18Ni11Ti | |||

WZPK2-240-dcP2 | ||||||

WZPK-241-dcP2 | ||||||

WZPK2-241-dcP2 | ||||||

WZCK-241-dcP2 | Cu50 Cu100 | -50~100 | -50~100 06Cr18Ni11Ti

|

所属分类:

所属分类: 打印当前页

打印当前页