In the field of oil, gas, chemical and other industries often accompanied by flammable, explosive, corrosion and other chemical gases, vapors and liquids, in order to automate industrial production, require temperature sensors to automate the process of measurement and control, and the use of aluminum Alloy flameproof junction box has been unable to meet the site explosion safety requirements.

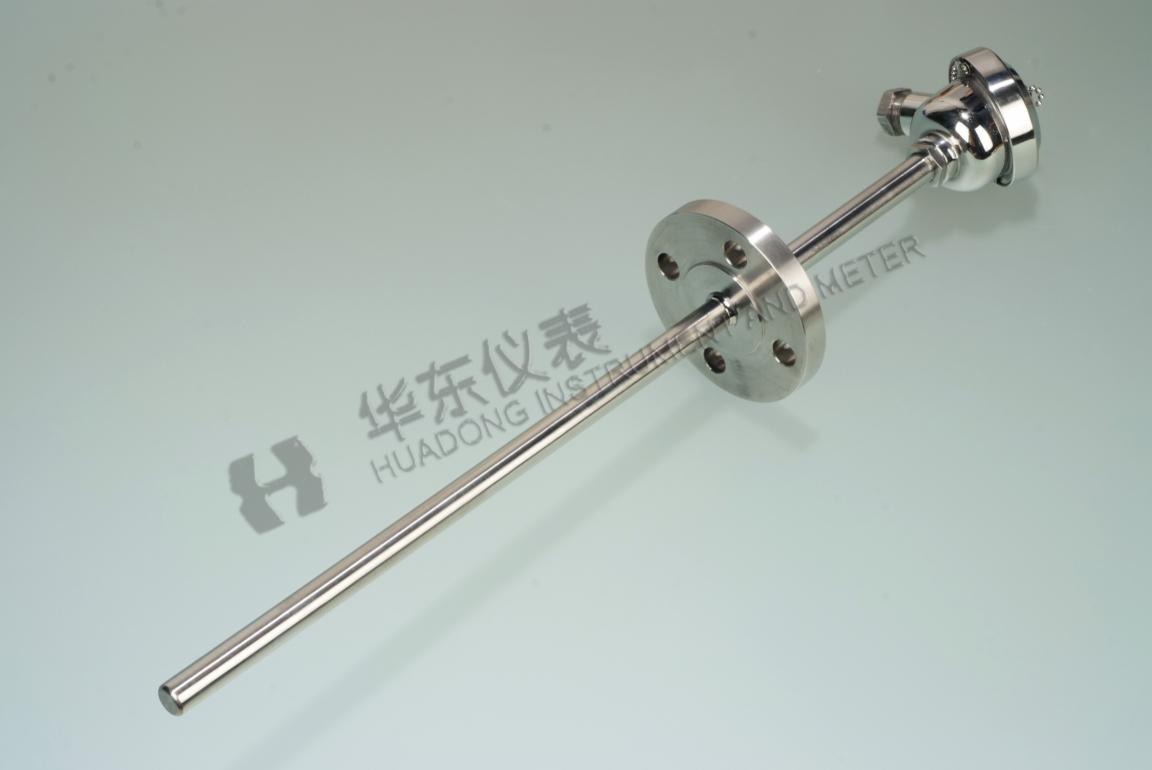

Flameproof thermocouple, thermal resistance, explosion-proof qualified testing by the state-level safety supervision and inspection station and certification issued by the explosion-proof series of product certification.

It uses all stainless steel junction box for Exd Ⅱ CT1 ~ 6 and requires the highest level of protection to IP65 with a corrosive and explosive atmosphere of the place.

1) temperature and tolerance

Type | Graduation | Tolerance level | |||

levelⅠ | level Ⅱ | ||||

Temperature range | Tolerance | Temperature range | Tolerance | ||

Nicrsi-Nisimg | N | 0~1000℃ | ±1.5℃ or ±0.4%∣t∣ | 0~1200℃ | ±2.5℃ or ±0.75%∣t∣ |

Ni-Cr – Ni-Si | K | ||||

Ni-Cr – Cu-Ni | E | 0~800℃ | ±1.5℃ or ±0.4%∣t∣ | 0~900℃ | ±2.5℃ or ±0.75%∣t∣ |

Type | Graduation | Temperature range | Tolerance level | ||

Pt Resistor | Pt100 | -200~500℃ | level A:±(0.15+0.002∣t∣)℃ | ||

level B:±(0.30+0.005∣t∣)℃ | |||||

Cu Resistor | Cu50 | -50~100℃ | ±(0.30+0.006∣t∣)℃ | ||

Cu100 | |||||

2) models and specifications

Type | Graduation | Temperature range/℃ | Thermal response time/s | Long-term use of temperature and material | specification Total length × insertion depth | Note |

WRNK-240-dcP2 | N | 0~1200 | τ0.5≤90 | 0~1200 K1230、GH1230 | 300×150 350×200 450×300 500×350 550×400 600×450 750×600 900×750 1150×1000 1250×1100 1400×1250 1500×1350 1650×1500 1750×1600 2000×1850 2150×2000

| 1, junction box: small stainless steel junction box (P2); 2, protection tube: thermocouple type 0,1 corresponding to φ16, φ20, thermal resistance model 0,1 corresponding to φ16, φ12; 3, commonly used connection size φ105 flange, sealing surface (B type) structure, optional other sizes. 4, temperature measurement components: single, double armored components φ3, φ4, φ5, φ6, φ8 or assembly components. |

WRNK2-240-dcP2 | ||||||

WRNK-241-dcP2 | 0~1100 GH30 | |||||

WRNK2-241-dcP2 | ||||||

WRKK-240-dcP2 | K | 0~1000(φ8) 1Cr25Ni20、Cr25Ti | ||||

WRKK2-240-dcP2 | ||||||

WRKK-241-dcP2 | 0~800 06Cr18Ni11Ti

| |||||

WRKK2-241-dcP2 | ||||||

WREK-240-dcP2 | E | 0~800 | 0~800 06Cr18Ni11Ti | |||

WREK2-240-dcP2 | ||||||

WREK-241-dcP2 | ||||||

WREK2-241-dcP2 | ||||||

WZPK-240-dcP2 | Pt100 | -200~500 | -200~500 06Cr18Ni11Ti | |||

WZPK2-240-dcP2 | ||||||

WZPK-241-dcP2 | ||||||

WZPK2-241-dcP2 | ||||||

WZCK-241-dcP2 | Cu50 Cu100 | -50~100 | -50~100 06Cr18Ni11Ti

|

所属分类:

所属分类: 打印当前页

打印当前页