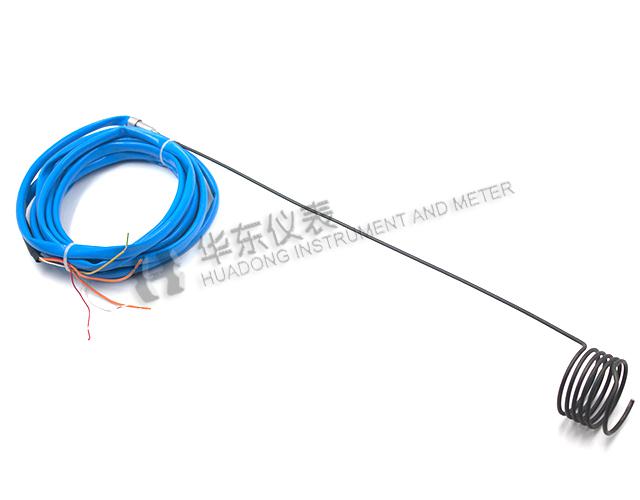

Ф3.0 Spring Coil heater is made of high-quality stainless steel,German heating wire,American high-purity magnesium oxide and strict technology, manufactured by automatic devices with independent intangible intellectual property rights. It could be used in the temperature as high as 650°C.And K,J or E type temperature control thermocouple can be built in the heater according to customer’s needs.Intergrated thermocouple can ensure accurate temperature control.

Using high-strength protective casing to the heater leads to be effective protection, the highest temperature casing up to 200 ℃, pressure up to 1.5kV.

There is an adjustable angel in one end of this product to ensure accurate temperature measurement of thermal couple and other parts adopt coil form. It could be used in casting technique and other electric heating industries, especially as hot runner mold system to provide quality electric heating.

Item | Standard Configuration | Selective Configuration |

Protective Tube Material | 321 | 304、316 |

Voltage | 230V | 220V、240V |

115W~200W Power Consumption Tolerance | +/-10% | —— |

201W~2000W Power Consumption Tolerance | +5%/-10% | —— |

Length After Coiled | 30~280mm | Based on Users’ Demands |

Length Tolerance | +/-1 | —— |

Inner Diameter Length After Coiled | 30~45mm | Based on Users’ Demands |

Inner Diameter Tolerance | -0.10mm | —— |

Length Of Unheating Zone | 600mm | Based on Users’ Demands |

Tolerance Length Of Unheating Zone | +/-5 | —— |

Cross Section | φ3 | Based on Users’ Demands |

Cross Section Tolerance | ±0.10mm | —— |

Integrated thermocouple | J | K、E |

Max Power Density | 9W/cm2 | —— |

Measurement Point For thermocouple | 7±2mm | Based on Users’ Demands |

Cold zone | 14±1mm | Based on Users’ Demands |

Max Working Temperature | 650℃ | —— |

Dielectric Strength | 700V | —— |

Cold zone | φ8×28mm | —— |

Max Outer Diameter Of Cold End | φ11.5 | Based on Users’ Demands |

Lead Wire Length | 4000mm | Based on Users’ Demands |

Sheath | Silica Glass Fiber Knitted Protecting Pipe, Blue | Orange, White Brown, Blue, White, Patterned |

Surface Processing | Blackened | Sand-Sprayed, Polished |

所属分类:

所属分类: 打印当前页

打印当前页